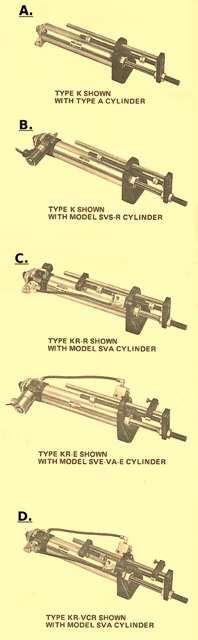

B. Automatic return – use with valve head SVA/SVE-VA only. If you have an air bleed or electrical signal it will go one cycle. The rod is stretched out on KRE and retracted on KRR. This kit is the same as “K” with an extra V2 valve, actuating arm and hardware you will need. C. Automatic reciprocating – this is made to work with valve in head unit SVA only. When air pressure is made available, the unit will instantly reciprocate. It is best to have a shut off valve put on the inlet line. The kit is same as “K” with extras – two V2 valves, actuating arms and hardware.

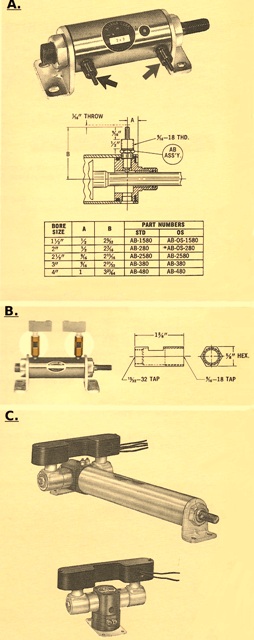

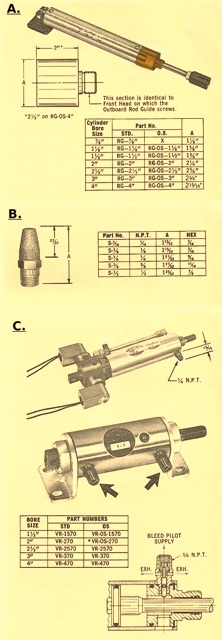

B. Sintered filter silencer – this lowers air exhaust noise t o a bearable level as not to restrict flow. If vent ports are use helps with particles from coming into the unit. C. Built in bleed valve – helps make other bleed valve on machinery actuated. Pu in a line from the bleeder pilot to the built in bleeder valve. Actuating starts 1/8″ ahead of full stroke of the cylinder being done. They can go in either direction or both ways. If you order put on there for the nomenclature “RF” means valve is put in on the front end, “RR” for rear end and “RB” both ends.